Remington 500V User Manual Page 26

- Page / 32

- Table of contents

- TROUBLESHOOTING

- BOOKMARKS

Rated. / 5. Based on customer reviews

26

106763

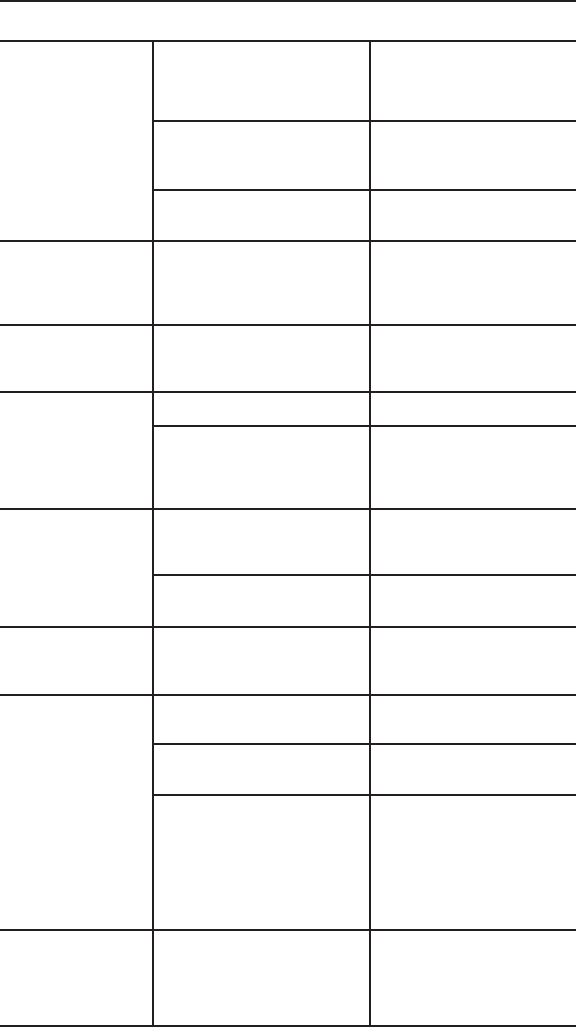

PROBLEM

Piston hangs out of

muzzle.

Overdriven fastener.

Piston jammed.

Power load strip will not

advance.

Reduction or loss of

power.

Tool does not com-

pletely depress.

Tool does not fire.

Opening and closing of

barrel or pushing down

on tool, etc. is not

smooth but is rough or

binds.

POSSIBLE CAUSE

Tool overdriven.

Piston not properly assembled in

relation to stop.

Broken piston or piston ring.

Excessive power.

Overdriving of fastener (see

above).

Advance bar or spring damaged

Tool dirty.

Piston not returning to full rear

position.

Worn piston ring or broken piston.

Misassembled or damaged sear,

firing pin parts, or guide.

Failure of tool to depress com-

pletely.

Piston not fully reset.

Dirt buildup on sear not allowing

proper penetration of firing pin or

worn firing pin.

Lack of proper cleaning.

REMEDY

Tap piston on hard surface until

piston is pushed back into the

guide. (See

Over-driven Fastener

below).

Remove barrel assembly (see

pages 18-21). Replace all dam-

aged or missing parts.

Replace piston or piston ring or

take tool to your distributor.

Change to next lower power indi-

cator setting and/or power load

level (see page 13) or use next

longer length fastener.

Remove barrel assembly (see

pages 18-21). Replace other

parts if damaged.

Replace advance bar or springs.

Clean tool. Notice: Do not at-

tempt to clean power load strip

channel with wire brush. You may

damage tool.

Barrel must be opened to the full

extended position to properly

position piston.

Replace piston and/or piston ring

or take tool to your distributor.

Remove firing pin guide and

check all parts for correct fit as-

sembly.

See data listed under T

ool does not

completely depress,

above.

Fully reset piston. See step 1 un-

der

Operation,

pages 14 and 15.

Check firing pin mark on power

load. Clean firing pin guide, sear

and firing pin. Replace worn or

damaged parts. Notice: Do not

attempt to clean power load strip

channel with wire brush. You may

damage tool.

Inspect and clean complete tool.

Replace worn or damaged parts.

Notice: Do not attempt to clean

power load strip channel with wire

brush. You may damage tool.

Troubleshooting Guide

- Model 500V 1

- REMINGTON 2

- Warning: Safety Precautions 3

- Safety Precautions 10

- Why A Power Fastener Holds 12

- Selecting Power Fasteners 13

- Operation 14

- Parts List 500V 16

- Cleaning and Maintenance 17

- Tool Disassembly 18

- Continued 19

- Tool Disassembly (Cont.) 20

- Tool Assembly 21

- Tool Assembly (Cont.) 22

- E. REPLACING FIRING PIN 23

- Troubleshooting Guide 26

- Technical Service 27

- Replacement Parts And 27

- Accessories 27

- Repair Service 27

- Parts Centrals 28

- Fasteners 28

- Application Chart 29

- Limited Warranty Agreement 32

(72 pages)

(72 pages)

Comments to this Manuals