Remington REM-05-240-GH Service Manual Page 30

- Page / 40

- Table of contents

- BOOKMARKS

Rated. / 5. Based on customer reviews

Recommended procedure for compressor

replacement

1. Be certain to perform all necessary electrical and

refrigeration tests to be sure the compressor is

actually defective before replacing.

2. Recover all refrigerant from the system though

the process tubes. PROPER HANDLING OF

RECOVERED REFRIGERANT ACCORDING TO

EPA REGULATIONS IS REQUIRED. Do not use

gauge manifold for this purpose if there has been

a burnout. You will contaminate your manifold and

hoses. Use a Schrader valve adapter and copper

tubing for burnout failures.

COMPRESSOR REPLACEMENT

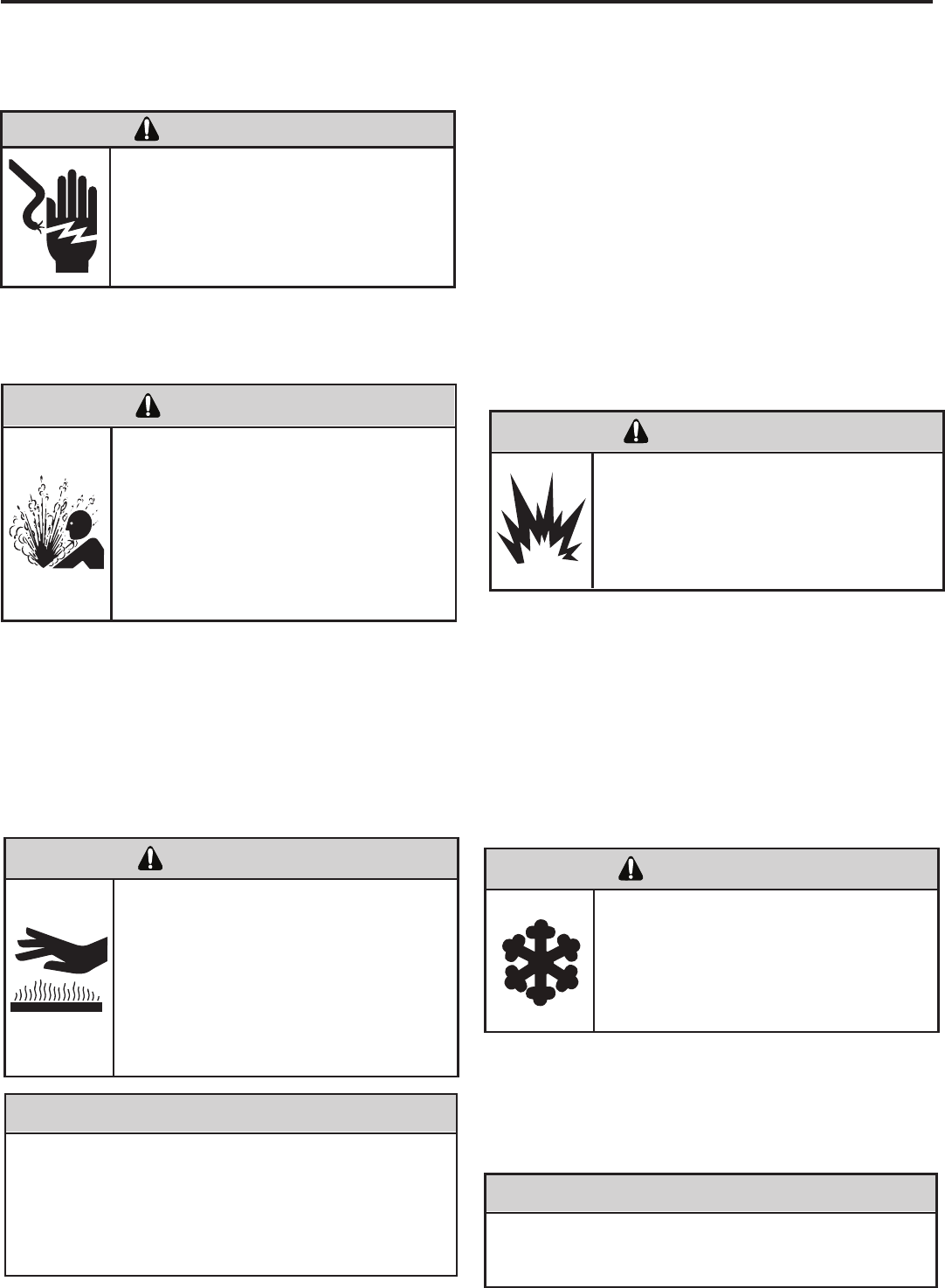

Unplug and/or disconnect all electrical power

to the unit before performing inspections,

maintenances or service.

Failure to do so could result in electric shock,

serious injury or death.

WARNING

RISK OF ELECTRIC SHOCK

Sealed Refrigeration System contains refrigerant

and oil under high pressure.

Proper safety procedures must be followed,

and proper protective clothing must be worn

when working with refrigerants.

Failure to follow these procedures could

result in serious injury or death.

WARNING

HIGH PRESSURE HAZARD

Extreme care, proper judgment and all safety

procedures must be followed when testing,

troubleshooting, handling or working around

unit while in operation with high temperature

components. Wear protective safety aids

such as: gloves, clothing etc.

Failure to do so could result in serious burn

injury.

WARNING

HIGH TEMPERATURES

The use of a torch requires extreme care and proper

judgment. Follow all safety recommended precautions

and protect surrounding areas with re proof materials.

Have a re extinguisher readily available. Failure to follow

this notice could result in moderate to serious property

damage.

NOTICE

FIRE HAZARD

3. After all refrigerant has been recovered, disconnect

suction and discharge lines from the compressor and

remove compressor. Be certain to have both suction

and discharge process tubes open to atmosphere.

4. Carefully pour a small amount of oil from the suction

stub of the defective compressor into a clean

container.

9. Evacuate the system with a good vacuum pump capable

of a nal vacuum of 200 microns or less. The system

should be evacuated through both liquid line and suction

line gauge ports. While the unit is being evacuated, seal

all openings on the defective compressor.

10. Recharge the system with the correct amount of

refrigerant. The proper refrigerant charge will be

found on the unit rating plate. The use of an accurate

measuring device, such as a charging cylinder,

electronic scales or similar device is necessary.

5. Using an acid test kit (one shot or conventional kit), test

the oil for acid content according to the instructions

with the kit.

6. If any evidence of a burnout is found, no matter how

slight, the system will need to be cleaned up following

proper procedures.

7. Install the replacement compressor.

8. Pressurize with a combination of R-410A and nitrogen

Repeat Step 8 to insure no more leaks are present.

The use of nitrogen requires a pressure

regulator. Follow all safety procedures and

wear protective safety clothing etc.

Failure to follow proper safety procedures

result in serious injury or death.

WARNING

EXPLOSION HAZARD

Proper safety procedures must be followed,

and proper protective clothing must be worn

when working with liquid refrigerant.

Failure to follow these procedures could

result in minor to moderate injury.

CAUTION

FREEZE HAZARD

and leak test all connections with leak detector capable of

detecting HFC (Hydrouorocarbon) refrigerant. Recover

refrigerant/nitrogen mixture and repair any leaks found.

NEVER, under any circumstances, charge a rotary

compressor through the LOW side. Doing so would

cause permanent damage to the new compressor.

NOTICE

28

- Service Manual – R410A Models 1

- TECHNICAL SUPPORT 2

- CONTACT INFORMATION 2

- Table of Contents 3

- IMPORTANT SAFETY INFORMATION 4

- ELECTRICAL HAZARDS: 5

- REFRIGERATION SYSTEM HAZARDS: 5

- INTRODUCTION 6

- UNIT IDENTIFICATION 7

- Component Identication 8

- Chassis Specications 9

- ELECTRICAL RATING TABLES 11

- CONTROL CONNECTIONS 12

- DIGITAL CONTROL OPERATION 15

- 12345678 16

- Diagnostics 17

- Escutcheon Kit Installed 17

- Remote Control 17

- Test Mode 18

- CAPACITORS 19

- COMPONENTS TESTING 19

- ELECTRIC SHOCK HAZARD 20

- Refrigerant Charging 22

- Method Of Charging / Repairs 23

- METERING DEVICE 25

- HERMETIC COMPONENTS CHECK 25

- TESTING THE COIL 26

- COMPRESSOR CHECKS 28

- External Overload 29

- Single Phase Resistance Test 29

- COMPRESSOR REPLACEMENT 30

- ROUTINE MAINTENANCE 31

- HEAT PUMP 33

- WIRING DIAGRAM INDEX 34

- WIRING DIAGRAM 35

- COOL WITH ELECTRIC HEAT 35

- HEAT PUMP WITH ELECTRIC HEAT 36

- TECHNICAL SERVICE DATA 38

- PD-ServMan-E (1-10) 40

Comments to this Manuals